News & Blogs 2022年07月11日

Guidelines | Influencing Factors of Coating Antibody of Bioeast Mag-COOH in Chemiluminescence Immunoassay

CN

CN

EN

News & Blogs 2022年07月11日

Guidelines | Influencing Factors of Coating Antibody of Bioeast Mag-COOH in Chemiluminescence Immunoassay

The surface modified magnetic beads used in the Magnetic Beads-based Chemiluminescence Immunoassay include carboxyl, benzenesulfonyl and streptavidin.

The application of magnetic beads with different active groups or antibody coupling methods is different. Today, we share some influencing factors in the coating antibody of Bioeast Mag-COOH.

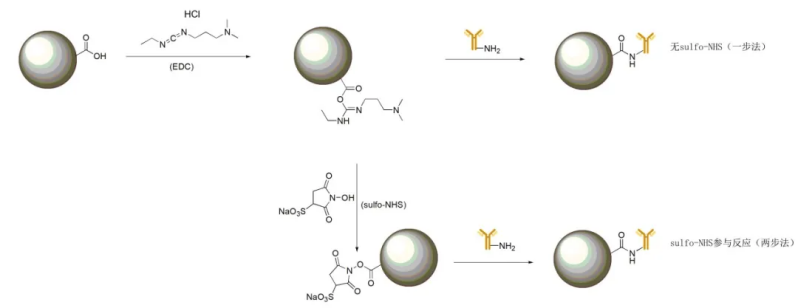

Coating Principle of Bioeast Mag-COOH

Bioeast Mag-COOH is the magnetic bead with modification on its surface by COOH, which can covalently bind to proteins by 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) activation. However, the intermediates formed by the EDC reaction are unstable in water and prone to hydrolysis. In order to prevent the activated intermediates from rapid hydrolysis and improve the coupling efficiency, Sulfo-N-hydroxysulfosuccinimide (Sulfo-NHS) can be added to the reaction to form more stable intermediates.

Coupling Principle of Bioeast Mag-COOH

Comparison of One-step Coating Method and Two-step Coating Method

The following protocols are adopted for the coating antibody using the three different test items of A, B and C:

(1) One-step coating method for Bioeast Mag-COOH, Test No.: one-step

(2) Two-step coating method for Bioeast Mag-COOH by only EDC activation, Test No.: two-step-EDC

(3) Two-step coating method for Bioeast Mag-COOH by EDC +NHS activation, Test No.: two-step-EDC+NHS

In accordance with the principle of control variable method, the magnetic beads under different coating processes are tested and verified.

Eva.1

Project A - Comparison of One-step Coating Method and Two-step Coating Method

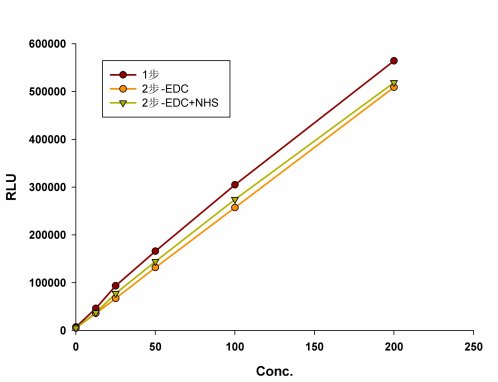

Comparison of Relative Light Units (RLU) Curve after One-step Coating Method and Two-step Coating Method in Project A

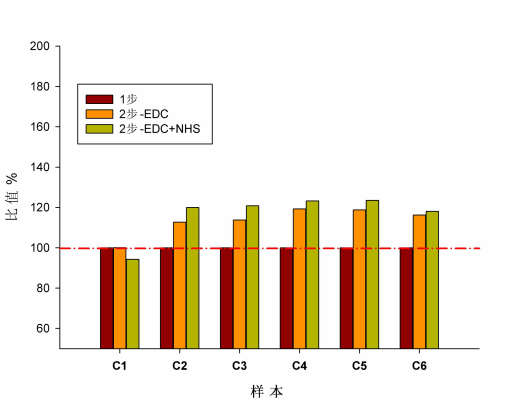

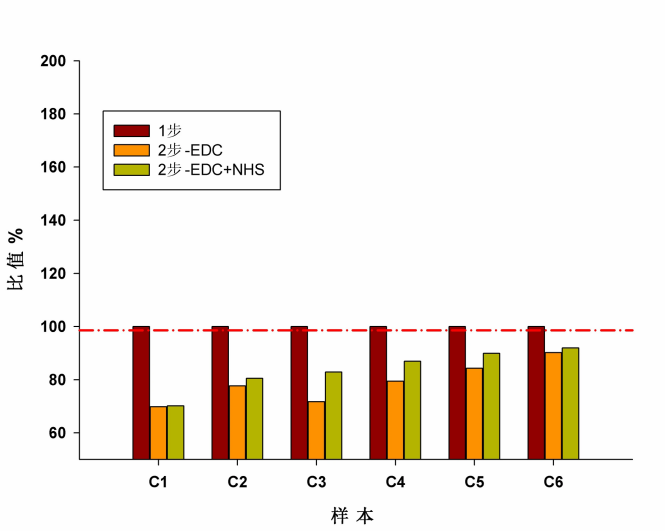

RLU Ratio of Each Sample Point in Project A

* Ratio% = (measured values under other coating protocols (RLU)) / (measured value under one-step coating protocol (RLU)) ×100--(Equation 1)

* The RLU of C2-C6 in Project A under 2 two-step coating methods is significantly higher than that of the one-step coating method. From the perspective of the RLU ratio at each point, the RLU of C1 (background) under the two-step coating method -EDC+NHS is lower, and the RLU of C2-C6 is higher.

Eva.2

Project B - Comparison of One-step Coating Method and Two-step Coating Method

Comparison of Relative Light Units (RLU) Curve after One-step Coating Method and Two-step Coating Method in Project B

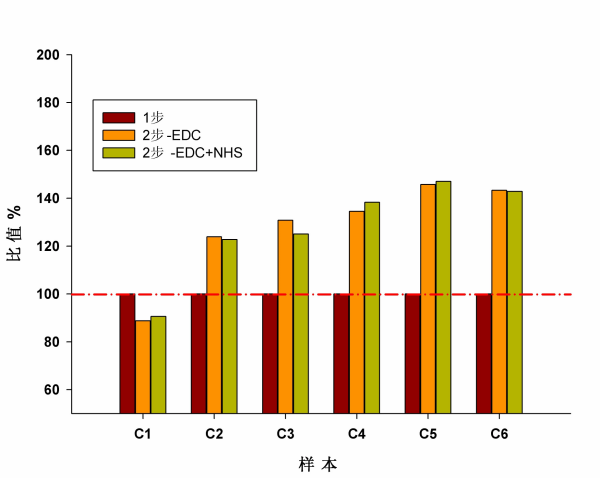

RLU Ratio of Each Sample Point in Project B: Refer to Equation 1

* The overall RLU of C1-C6 under the one-step coating method in Project A is higher than that of the two-step coating method, but according to the results of the two-step coating method, the C1 value (background) is lower.

Eva.3

Project C - Comparison of One-step Coating Method and Two-step Coating Method

Comparison of Relative Light Units (RLU) Curve after One-step Coating Method and Two-step Coating Method in Project C

RLU Ratio of Each Sample Point in Project C: Refer to Equation 1

* The RLU of C2-C6 in Project C under 2 two-step coating methods is significantly higher than that of the one-step coating method. From the perspective of the RLU ratio at each point, there is no significant difference in RLU between the 2 two-step coating methods.

Discussion

* The difference of RLUs displayed under the three coating methods is different for different test items.

* Among the 2 two-step coating methods, the test results in the reaction with NHS are slightly better than those of the reaction without NHS.

The performance of different test items or coating antibodies is also different under different coating protocols. According to the three groups of test results shown so far, the two-step coating method is more applicable, but the one-step coating process is simpler than the two-step coating method. We recommend: A comparative test can be carried out to determine whether one-step or two-step coating method is used during your application; if you adopt the two-step coating method, we recommend that you use the method with NHS involved in the reaction.

Comparison of Coating pH

Two different test items A and B were used, and the coating antibodies were coated with one-step coating method and two-step coating method. In accordance with the principle of control variable method, the magnetic beads under different coating pH are tested and verified.

Note: The two-step coating method of the test involves EDC and NHS; coating pH refers to the pH value of coating buffer.

Eva.4

Project A- Comparison of Coating pH

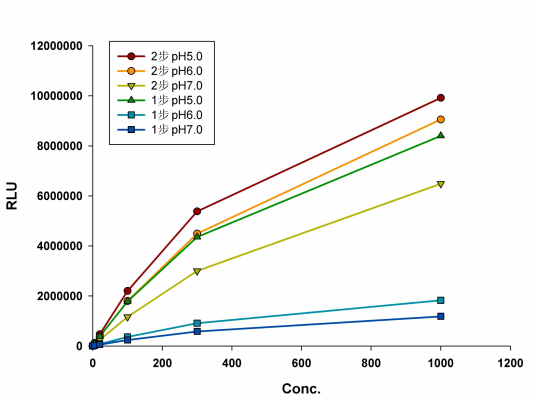

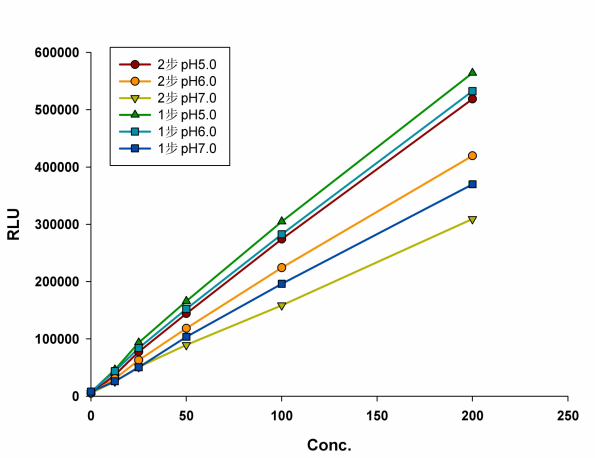

Project A-Comparison of RLU Curve after One-step Coating Method and Two-step Coating Method under the Different pH Values

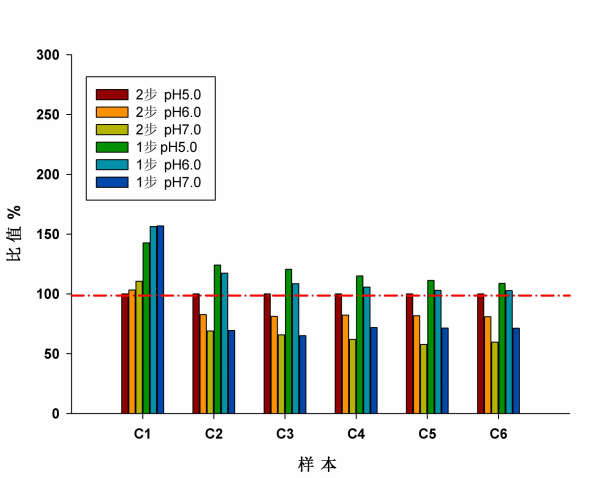

RLU Ratio of Each Sample Point in Project A

* Ratio% = (measured value under other coating protocols (RLU)) / (measured value under two-step coating protocol at pH 5.0 (RLU)) ×100--(Equation 2)

* Under the protocol of one-step coating method, the RLU decreases rapidly with the increase of pH value, while under the same condition of two-step coating method, the decrease ratio of RLU is obviously lower than that of the one-step coating method. No obvious condensation was observed visually during the coating process with one-step coating method and two-step coating method.

Eva.5

Project B- Comparison of Coating pH

Project B-Comparison of RLU Curve after One-step Coating Method and Two-step Coating Method under the Different pH Values

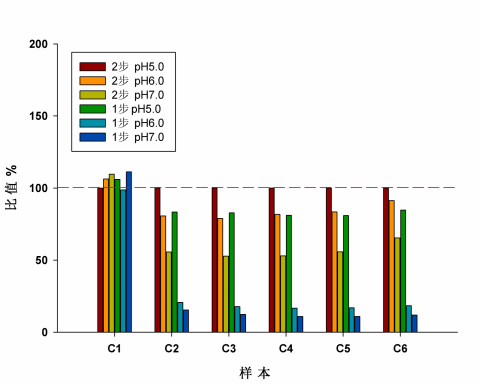

RLU Ratio of Each Sample Point in Project B: Refer to Equation 2

Discussion

* The highest RLU of Project A and Project B under the one-step coating method and two-step coating method are at pH=5.

* There will be different degrees of condensation by one-step coating method under different coating antibodies and different coating pH conditions.

The sensitivity of different projects and different coating protocols to pH value is different, and the recommended coating pH in this laboratory is 5.0. However, due to the differences of different items or antibodies, in order to obtain the optimal coating conditions, it is recommended that you screen the pH gradient during application, and the screening range for pH value is recommended to be 4.0 –7.0.